PTFE Back Up

Product Details:

- Type Back-Up Ring

- Material PTFE (Polytetrafluoroethylene)

- Working Temperature -200C to +260C

- Density 2.3 Gram per cubic centimeter(g/cm3)

- Corrosion Protection Excellent chemical resistance

- Tensile Strength 21 MPa

- Thickness Available in standard and custom thickness

- Click to View more

X

PTFE Back Up Price And Quantity

- 1 , , Piece

PTFE Back Up Product Specifications

- Customizable

- Excellent chemical resistance

- 2.3 Gram per cubic centimeter(g/cm3)

- 21 MPa

- Back-Up Ring

- As per requirement

- 327C

- PTFE (Polytetrafluoroethylene)

- Available in standard and custom thickness

- -200C to +260C

- As per requirement

PTFE Back Up Trade Information

- 500 , , Piece Per Day

- 2-3 Days

Product Description

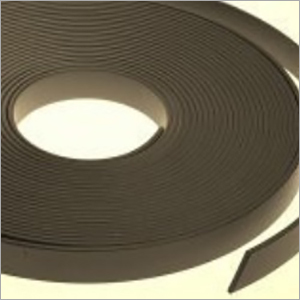

PTFE back Up spares are reckoned for their abrasion and chemical proof design. These polytetrafluoroethylene products are high temperature proof and these are chemically inert. Moreover, their original standard remains intact even after their exposure to high and low temperature. PTFE back Up spares are contamination proof and have excellent anti aging characteristics. These hydraulic spare accessories can be used under different pressure, temperature and chemical prone environments. Standard of these products has been tested on the basis of their diameter, raw material selection, processing method and durability. White in color, these back up accessories can be availed in different shapes and sizes to suit exact application requirements.

High-Quality PTFE Material

Manufactured using virgin PTFE (Polytetrafluoroethylene), these back-up rings combine high tensile strength (21 MPa) and density (2.3 g/cm) for longevity in hydraulic and pneumatic systems. The material ensures outstanding resistance to chemical corrosion and non-stick that facilitates reliable sealing performance under harsh conditions.

Customizable Sizes for Versatile Applications

The PTFE back-up rings are available in standard and custom sizes, thicknesses, and widths, catering to various requirements in sealing systems. This flexibility supports their use in a wide range of industries, providing tailored solutions for both OEM and aftermarket applications.

Advanced Manufacturing Techniques

Each ring is produced using moulded or lathe-cut techniques to achieve precise dimensions and a smooth surface finish. Expert manufacturing ensures consistent quality, enhancing the rings performance and reliability in critical hydraulic or pneumatic assemblies.

FAQs of PTFE Back Up:

Q: How are PTFE Back-Up Rings used in hydraulic and pneumatic sealing applications?

A: PTFE Back-Up Rings are installed alongside O-rings in hydraulic and pneumatic systems to prevent extrusion under pressure, enhancing the longevity and reliability of the seal. Their low friction and non-corrosive properties make them ideal for demanding environments.Q: What manufacturing process is utilized for these back-up rings?

A: These rings are produced using either moulded or lathe-cut techniques. Both processes ensure precise dimensions and a smooth surface finish, resulting in high-quality back-up rings that meet stringent industrial standards.Q: Where can PTFE Back-Up Rings be applied?

A: They are suitable for hydraulic and pneumatic systems, including cylinders, pumps, valves, and actuators in industries such as automotive, aerospace, chemical, and general engineering.Q: What benefits do PTFE Back-Up Rings offer over conventional sealing components?

A: PTFE Back-Up Rings provide exceptional durability, excellent chemical resistance, and low friction. Their non-stick and smooth surface extends the lifespan of sealing systems and maximizes efficiency in extreme temperatures.Q: What is the water absorption rate of these rings and why is it important?

A: The water absorption rate is less than 0.01%, ensuring that the rings maintain their dimensional stability and mechanical integrity even in humid or wet environments.Q: When should custom sizes or thicknesses be selected for PTFE Back-Up Rings?

A: Custom sizes and thicknesses should be chosen when standard dimensions do not fit the specific application requirements, allowing optimal performance and a precise fit in unique sealing assemblies.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PTFE Hydraulic Spares' category

|

DHWANI POLYMER INDIA PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |